The Gas Line Size Calculator is a simple, easy-to-use tool designed to help you determine the required size of a gas line for a particular appliance based on its maximum BTU (British Thermal Unit) rating.

Disclaimer: This calculator estimates pipe size based on the criteria provided. It does not constitute professional advice or replace proper consultation for specific applications.

For a more accurate determination of the required gas line size, it is always best to consult with a licensed professional or your local gas company.

Gas Line Size BTU Chart

| PIPE SIZE (inches) | Actual ID | 10 ft | 20 ft | 30 ft | 40 ft | 50 ft | 60 ft | 70 ft | 80 ft | 90 ft | 100 ft | 125 ft | 150 ft | 175 ft | 200 ft | 250 ft | 300 ft | 350 ft | 400 ft |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2” | 0.622 | 172 | 118 | 95 | 81 | 72 | 65 | 60 | 56 | 52 | 50 | 44 | 40 | 37 | 34 | 30 | 27 | 25 | 23 |

| 3/4” | 0.824 | 360 | 247 | 199 | 170 | 151 | 137 | 126 | 117 | 110 | 104 | 92 | 83 | 77 | 71 | 63 | 57 | 53 | 49 |

| 1” | 1.049 | 678 | 466 | 374 | 320 | 284 | 257 | 237 | 220 | 207 | 195 | 173 | 157 | 144 | 134 | 119 | 108 | 99 | 92 |

| 1 1/4” | 1.380 | 1,390 | 957 | 768 | 657 | 583 | 528 | 486 | 452 | 424 | 400 | 355 | 322 | 296 | 275 | 244 | 221 | 203 | 189 |

| 1 1/2” | 1.610 | 2,090 | 1,430 | 1,150 | 985 | 873 | 791 | 728 | 677 | 635 | 600 | 532 | 482 | 443 | 412 | 366 | 331 | 305 | 283 |

| 2” | 2.067 | 4,020 | 2,760 | 2,220 | 1,900 | 1,680 | 1,520 | 1,400 | 1,300 | 1,220 | 1,160 | 1,020 | 928 | 854 | 794 | 704 | 638 | 587 | 546 |

| 2 1/2” | 2.469 | 6,400 | 4,400 | 3,530 | 3,020 | 2,680 | 2,430 | 2,230 | 2,080 | 1,950 | 1,840 | 1,630 | 1,480 | 1,360 | 1,270 | 1,120 | 1,020 | 935 | 870 |

| 3” | 3.068 | 11,300 | 7,780 | 6,250 | 5,350 | 4,740 | 4,290 | 3,950 | 3,670 | 3,450 | 3,260 | 2,890 | 2,610 | 2,410 | 2,240 | 1,980 | 1,800 | 1,650 | 1,540 |

| 4” | 4.026 | 23,100 | 15,900 | 12,700 | 10,900 | 9,660 | 8,760 | 8,050 | 7,490 | 7,030 | 6,640 | 5,890 | 5,330 | 4,910 | 4,560 | 4,050 | 3,670 | 3,370 | 3,140 |

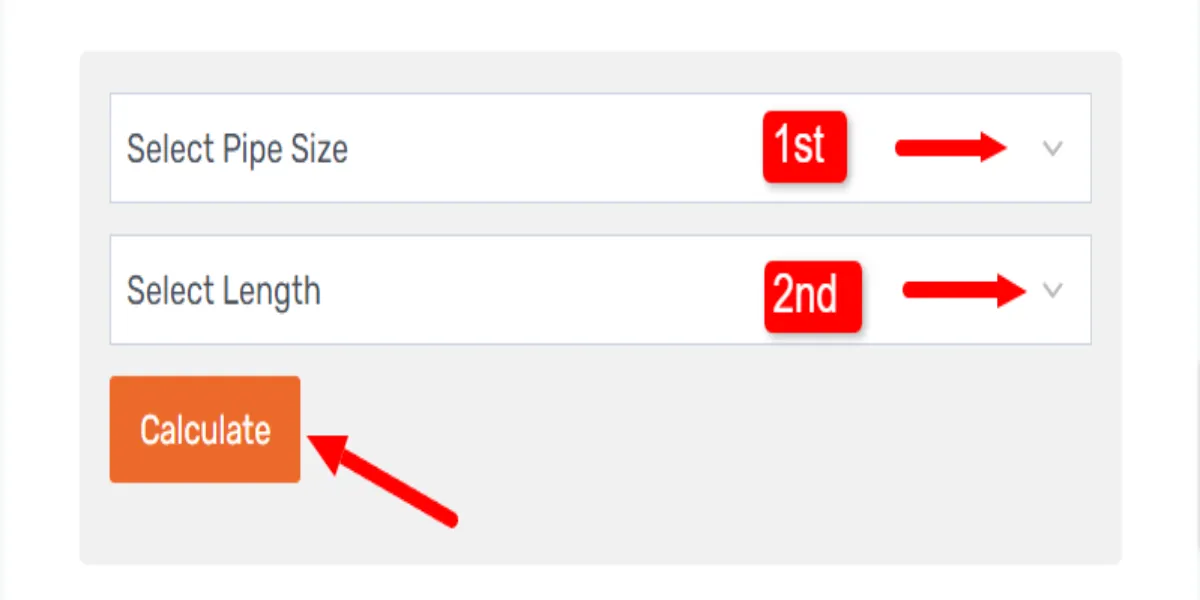

Calculate the Gas Pipe Size For Your Gas Line

The given table provides the recommended gas line sizes (in inches) based on the actual internal diameter (ID) and the length of the pipe run (in feet).

The table also specifies the maximum BTU (British Thermal Units) that each pipe size can handle for different lengths.

To calculate the appropriate gas pipe size based on BTU and pipe length, you would do the following:

- Find Pipe Length: Determine the length of the pipe you need. This will be one of the columns in your table (10 ft, 20 ft, etc.).

- Check BTU: Look at the BTU requirements for your gas application. This is the number you will use to find the right pipe size.

- Match BTU and Length: Once you know the BTU and pipe length, look for the row where your BTU is lower or equal to the value in the table and under the column for your pipe length.

- Find Pipe Size: Once you’ve identified the appropriate row, look at the “PIPE SIZE (inches)” column to find the recommended pipe size.

Let’s say you have a natural gas application that requires a maximum of 400 BTUs, and you’re planning to have a pipe length of 40 feet. Here’s how you would use the table to find the appropriate pipe size:

- Find Pipe Length: You know that your pipe length is 40 feet, so you’ll look at the column labeled “40 ft” in the table.

- Check BTU: Your application requires a maximum of 400 BTUs.

- Match BTU and Length:

- In the “40 ft” column, start from the top and go down until you find a number that is greater than or equal to 400.

- For a 40-foot length, the BTU capacities are: 81 (for 1/2″), 170 (for 3/4″), 320 (for 1″), 657 (for 1 1/4″), 985 (for 1 1/2″), etc.

- The first BTU value greater than or equal to 400 is 657, which is for a 1 1/4″ pipe.

- Find Pipe Size: The recommended pipe size for a maximum of 400 BTUs with a 40-foot length is 1 1/4″ based on the table.

Understanding British Thermal Units (BTU)

British Thermal Units (BTUs) are a unit of energy measurement and a key factor when sizing gas lines.

The amount of BTUs needed for any given application is determined by the total output of the appliance and its fuel type.

A BTU is defined as the amount of energy needed to raise the temperature of one pound of water by one degree Fahrenheit, and it is typically used to measure heat output from appliances like furnaces, stoves, ovens and hot water tanks.

When it comes to sizing gas lines for these appliances, an accurate calculation of BTUs is essential in order to ensure that the line can safely handle the volume of gas flowing through it.

Sizing a gas line too small can lead to dangerous pressure build-up and inadequate delivery of fuel, resulting in poor performance from your appliance.

On the other hand, sizing it too large will increase costs with no corresponding benefit.

The number of BTUs needed for a particular appliance depends on its type and size.

For example, a small kitchen stove may require around 20k BTU/hr while a larger industrial model may require up to 200k BTU/hr or more.

Importance Of Proper Gas Line Sizing

When installing or modifying a gas line, it’s essential to take into account the size of the gas line.

A gas line that is too small can lead to reduced efficiency and higher energy costs, while a pipe that is oversized can be wasteful and dangerous.

The British Thermal Unit (BTU) rating of the appliance being used should also be taken into consideration when selecting a pipe size

This will determine the amount of energy needed to power the appliance as well as how much heat needs to be delivered to it.

The BTU rating is listed on all gas appliances and should match up with the size of the pipe used in order to ensure proper functioning.

An undersized pipe may not provide sufficient pressure for a given appliance, resulting in an inadequate supply of fuel and potential safety issues such as incomplete combustion of fuel which can potentially release harmful gases into the atmosphere.

On the other hand, an oversized pipe may result in excessive delivery of fuel leading to more wasted energy than needed, higher utility bills and potential fire risks.

In order to calculate precisely what size pipe you need for your particular situation, you’ll need a Gas Line Size Calculator BTU tool which can help you determine exactly what kind of gas line sizing is best suited for your needs.

This calculator takes into account factors such as gas type, BTU rating, total length of piping and number of bends or fittings in order to determine what size will provide optimal performance for your system.

By taking these important variables into account before installation, you can be sure that your system is safe and efficient for years to come!

Factors Affecting Gas Line Size

The size of a gas line is an important factor to consider when planning any project that utilizes natural gas.

It is important to select the right size of pipe for a given application in order to ensure safe and efficient operation.

The following factors should be taken into consideration when determining the optimal gas line size:

Flow Rate:

The amount of gas flowing through the line will be a major factor in determining its size.

Higher flow rates require larger pipes, while lower flow rates allow for smaller pipes.

Pressure:

The pressure of the gas within the line will also play a role in determining the proper pipe size.

High-pressure systems typically require larger pipes than low-pressure systems.

Length:

Longer pipelines require larger pipes than shorter ones due to increased friction losses over distance.

Environment:

Certain environments may necessitate different types and sizes of pipes based on local codes and regulations.

For example, some areas may require special type piping for underground or exterior applications.

It is important to understand these factors in order to properly determine the correct pipe size for your project.

A Gas Line Size Calculator BTU can be used to help calculate the maximum BTU capacity that can safely be carried by a given pipe size and length, ensuring a safe and efficient installation.

How To Determine Maximum BTU

One of the most important steps in sizing a gas line is determining the total output BTUs needed by the appliance or appliances that will be connected to it.

The BTU rating of an appliance can be found in its manual or on the manufacturer’s website and is typically expressed in BTUs per hour (BTUs/hr).

Once you know the BTU requirement of the appliances you will be connecting to the gas line, you can use this information to calculate the maximum BTU capacity of the line.

The maximum BTU capacity is the total amount of BTUs that the line must be able to support in order to ensure proper operation of the appliance or appliances.

Tips For Using A Gas Line Size Calculator

Accurately determining the proper size of a gas line is essential for any project involving gas-powered appliances.

A gas line size calculator BTU can help users determine the right size to ensure they are meeting safety and efficiency requirements.

When using a gas line size calculator BTU, it’s important to know what factors will affect the calculation and how to use the tool correctly.

When using a gas line size calculator BTU, there are several tips that should be followed for best results.

First, users should understand all of the input values that are necessary to make an accurate calculation.

This includes knowing the total length of the pipe, as well as any bends or drops in elevation along the route of the pipe run.

It’s also important to correctly enter information about each individual appliance that will use gas through this line, such as its type, model number, and maximum BTU rating.

Another tip when using a gas line size calculator BTU is to consider any potential additional appliances added in the future.

If it’s likely that more appliances might be connected down the road, it’s wise to plan ahead and select a pipe size that will accommodate those additional items without needing modifications or upgrades later on.

This helps ensure long-term safety and efficiency for all connected appliances.

Finally, if possible it’s helpful to choose a mobile-friendly version of a gas line size calculator so you can access it from anywhere in order to double check your calculations or do quick computations onsite during installation or repairs

Being able to take advantage of mobile technology can save time and energy when doing complex calculations associated with gas lines.

5 Common Mistakes to Avoid When Sizing Gas Lines

1. Neglecting to Measure the Length of the Gas Line

Measuring the length of the gas line is an essential step in correctly sizing it.

If you don’t know how long the pipe needs to be or take into account future expansion, then you may end up with a line that’s too short or doesn’t have enough capacity.

It’s important to always measure and account for the entire length before selecting a pipe size.

2. Underestimating the Needed Capacity

When sizing a gas line, it is important to make sure you accurately calculate the capacity needed.

Failing to do so could result in an inadequate supply and a potential safety hazard.

If you underestimate the amount of gas that needs to be supplied, your system will not function properly and you may experience issues with performance or pressure.

Make sure to take into account all factors that influence the amount of gas needed before selecting a pipe diameter for your system.

3. Choosing Too Small of a Pipe Diameter

When selecting the proper pipe diameter for a gas line, it’s important to avoid choosing one that is too small.

If you choose a pipe diameter that is too small, the gas may not be able to flow through it properly and could cause pressure issues or even blockages in the line.

To ensure that you select the correct pipe diameter for your needs, take into account the length of the gas line, as well as its expected capacity and pressure requirements.

4. Failing to Understand Pressure Requirements

When sizing a gas line, it is important to understand the pressure requirements that are needed for the project.

This means taking into account the pressure of the gas being transported and ensuring that the line is able to handle this pressure without rupturing or causing any other safety issues.

Failing to adequately assess and understand these pressure requirements can lead to significant problems down the road.

5. Ignoring Manufacturer Recommendations

When sizing a gas line, it is essential to consider the manufacturer’s recommendations.

This is because different types of gas may require different sizes of lines and fittings, as well as other considerations such as pressure requirements.

Failing to adhere to the manufacturer’s instructions can lead to improper installation or even dangerous conditions.

Taking the time to read and understand any applicable instructions will help ensure that your gas line is properly sized for safe and efficient operation.

Final Thoughts

In conclusion, a gas line size calculator BTU is a valuable tool for anyone who needs to determine the size of a gas line for a heating system or appliance.

Proper gas line sizing is essential to ensure the safe and efficient operation of these systems.

By considering factors such as the maximum BTU and the length of the gas line, a gas line size calculator can help you determine the ideal size for your specific needs.