Choosing the right wire size for a 15-amp circuit is crucial for safety and efficiency. This blog will guide you through the factors influencing your choice, from material composition and current carrying capacity to insulation type and local electrical codes.

We’ll help you avoid common mistakes and ensure your electrical system is up to standard. Stay tuned for an enlightening journey into the world of electrical wiring!

What Size Wire for a 15 Amp Circuit?

For a 15 amp circuit, the ideal wire size is 14-gauge. However, some contractors consider 12-gauge wire as a 15a wire gauge. If you choose to use aluminum wire, the correct size for a 15 Amp breaker is 12 AWG.

15 amp Circuit Wire Size Chart:

| Wire Gauge | Type | Common Uses |

| 14 | Copper | Lighting circuits |

| 12 | Aluminum | Outlet circuits |

| 10 | Tinned | Appliance circuits |

Different Types of Wires Suitable for a 15 Amp Circuit

Copper Wires

Copper wires are a popular choice for 15 Amp circuits. Here’s why:

Advantages:

- High Conductivity: Copper is known for its excellent electrical conductivity. This means electricity can pass through it very easily, making it ideal for electrical wiring.

- Corrosion Resistance: Copper wires are resistant to corrosion. This means they can last a long time without being damaged by rust.

Disadvantages:

- Cost: The main downside of copper wires is their cost. Copper is a valuable metal, and this is reflected in the price of copper wires.

Aluminum Wires

Aluminum wires are another option for 15 Amp circuits. Here’s what you need to know:

Advantages:

- Lightweight: Aluminum wires are lighter than copper wires. This can make them easier to work with, especially in large quantities.

- Cost-effective: Aluminum is less expensive than copper, making aluminum wires a more affordable option.

Disadvantages:

- Lower Conductivity: Aluminum isn’t as conductive as copper. This means that you might need a thicker aluminum wire to carry the same amount of electricity as a thinner copper wire.

- Corrosion: Aluminum can corrode over time, especially when it comes into contact with certain types of metal. This can lead to safety issues if not properly managed.

Tinned Wires

Tinned wires are less common but still have their uses. Here’s what you should know:

Advantages:

- Corrosion Resistance: Tinned wires are highly resistant to corrosion, even more so than copper wires. This makes them a great choice for environments where corrosion is a concern, such as in marine applications.

Disadvantages:

- Cost: Tinned wires are typically more expensive than both copper and aluminum wires due to the additional process of coating the wire with tin.

How to Determine the Appropriate Wire Size for a 15 Amp Circuit

Length of the Circuit Run

The longer the circuit, the larger the wire size you’ll need. This is to prevent voltage drops, which can affect the performance of your electrical devices.

Type of Load

Different electrical devices (or loads) require different amounts of current. For example, a light bulb might only need a small amount of current, while a large appliance like a refrigerator needs more.

Make sure to consider what devices will be on the circuit when choosing your wire size.

Ambient Temperature

The temperature around the wire can affect its performance. If it’s very hot, the wire might not be able to carry as much current. So, in warmer environments, you might need a larger wire size.

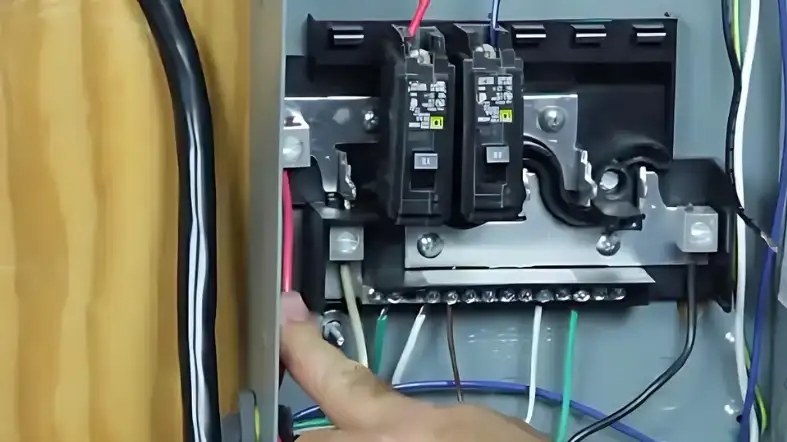

Determine the breaker’s amperage rating

The amperage rating of the breaker will determine the maximum current that the wire needs to handle. This information is typically printed on the breaker itself.

Consider the type of wire

Copper cables are generally a better choice for 15 Amp circuits. If you choose to use aluminum wire, the correct size for a 15 Amp breaker is 12 AWG.

Use a wire gauge chart

The wire is sized by gauge, which refers to the diameter of the wire. Consult a wire gauge chart to determine the appropriate wire size based on the amperage rating of the breaker and the load of the circuit.

Consider safety factors

It’s important to ensure that the wire size can handle the maximum current without overheating. Keep in mind that you can only load a breaker to 80% of its capacity.

Online Calculators

There are online tools that can help you determine the right wire size for your specific situation.

You just need to input your circuit details (like length and load type), and the calculator will give you a recommended wire size.

Factors Influencing Wire Size Selection for a 15 Amp Circuit

Material Composition

The wire’s material composition plays a crucial role in its conductivity. For instance, copper wires are commonly used due to their high conductivity. However, aluminum wires, while less conductive, are lighter and more affordable.

Current Carrying Capacity

The wire size should be chosen based on the maximum current it can safely carry. Generally, the wire size should be selected to safely carry 125% of the breaker’s rated current, which in this case would be 18.75 amps.

Insulation Type

The insulation type affects the wire’s heat resistance. PVC insulation is common, but if the wire is expected to face higher temperatures, insulation materials like Teflon might be used.

Installation Conditions

The performance of the wire can be influenced by installation conditions. For example, wires running through hot attics might need to be rated for higher temperatures.

Wires installed in damp or wet areas may also require additional insulation or protection.

Ambient Temperature

The surrounding temperature can affect the wire’s current carrying capacity. Consult the National Electrical Code (NEC) or local electrical regulations to determine the appropriate wire size based on the ambient temperature. In hotter environments, the wire might carry less current.

Voltage Drop Considerations

Voltage drop is a decrease in electrical potential along the path of a power source. Long circuit runs can cause significant voltage drops, which need to be considered when choosing the wire size.

Length of the Circuit Run

Longer runs require thicker wires to prevent voltage drop. For instance, a 15 Amp circuit with a long run might require a 12-gauge wire instead of the typical 14-gauge.

Safety Standards and Regulations

The chosen wire size should comply with local electrical codes and safety standards. These standards ensure that the electrical installation is safe and efficient.

Equipment and Appliances Used

The type of equipment and appliances used on the circuit can affect the required wire size. High-power appliances might require thicker wires.

Local Electrical Codes

Local electrical codes may dictate specific requirements for wire sizes. Always check with local authorities or a licensed electrician when planning an electrical installation.

Consult a Professional

If you’re unsure about selecting the appropriate wire size for a 15 Amp circuit, it’s always best to consult a professional electrician.

They have the knowledge and expertise to assess your specific electrical needs and ensure that the wire size is appropriate for the circuit.

Common Mistakes to Avoid When Choosing Wire Size

When choosing a wire size for a 15 Amp circuit, there are several common mistakes to avoid:

Ignoring Material Composition

Different materials have varying levels of electrical conductivity. For instance, copper is more conductive than aluminum, but it’s also more expensive.

Choosing the wrong material can lead to inefficient circuits or higher costs.

Overlooking Current Carrying Capacity

Each wire size has a maximum current it can safely carry. Ignoring this can lead to overheating and potential fire hazards.

Always match the wire size with the circuit’s current requirements.

Neglecting Insulation Type

The insulation type affects a wire’s heat resistance and overall safety. Using a wire with inadequate insulation for the environment can lead to insulation breakdown and electrical faults.

Disregarding Installation Conditions

Installation conditions, such as whether the wire is in a conduit or exposed to sunlight, can affect its performance.

Failing to consider these conditions can lead to premature wire failure.

Forgetting About Ambient Temperature

Higher ambient temperatures can decrease a wire’s current carrying capacity. If you don’t account for this, you may end up with a wire that can’t safely carry the circuit’s current.

Not Considering Voltage Drop

Longer circuit runs can cause significant voltage drops, leading to underpowered devices.

Always consider the length of the circuit run when choosing a wire size.

Overlooking Safety Standards and Regulations

Local electrical codes and safety standards dictate minimum requirements for wire sizes. Ignoring these standards can lead to unsafe installations and potential legal issues.

Not Considering Equipment and Appliances Used

The type of equipment and appliances on the circuit affect the required wire size. High-power appliances may require thicker wires, so always consider what devices will be used on the circuit.

Ignoring Local Electrical Codes

Local electrical codes often have specific requirements for wire sizes. Failing to adhere to these codes can result in fines or required modifications to your electrical system.

FAQs

Is aluminum wire suitable for a 15-amp circuit?

Aluminum wire is generally not recommended for smaller circuits like 15-amp circuits; stick with copper.

How long can the wire run be for a 15-amp circuit?

For a 14-gauge wire on a 15-amp circuit, a length up to 50 feet is typically okay for a drop in voltage under 3%.

Is it safe to use a larger wire size, like 12-gauge, for a 15-amp circuit?

Yes, it’s safe to use a 12-gauge wire for a 15-amp circuit. Using a larger wire will not pose a safety risk.

What type of insulation is recommended for 14-gauge wire in a 15-amp circuit?

THHN/THWN insulation is commonly used for interior wiring in 15-amp circuits.

Conclusion

Choosing the right size wire for a 15 Amp circuit is crucial for safety and efficiency. Always consider the factors that we’ve mentioned above when making your decision.

Avoid common mistakes like choosing an undersized wire to ensure your circuit operates safely and efficiently.