Understanding what size wire for oven is crucial to avoid overheating, reduced performance, damage to the oven, and even safety hazards.

Conversely, choosing the right wire size ensures the safe and efficient operation of your oven.

However, the wire size for an oven depends on several factors, including the oven’s wattage, voltage, and the length of the wire run.

In this blog post, we’ll explore the ways of choosing the right size wire for the oven and provide valuable insights to help you make an informed decision.

Quick answer: What Size Wire for an Oven?

For an oven that uses 110-120 volts and has a current draw of 30 amps, you would need a 10 gauge wire. If the oven is 240 volts and still has a current draw of 30 amps, you would need a 6 gauge wire.

Here’s a table chart that shows the recommended wire sizes for different oven wattages:

| Voltage (V) | Amperage (A) | Copper Wire Gauge | Aluminum Wire Gauge | Oven Wattage (W) |

| 110-120 | 30 | 10 | 8 | 2,000-5,000 |

| 240 | 30 | 8 | 6 | 2,000-5,000 |

What Size Wire for an Oven? Brief discussion

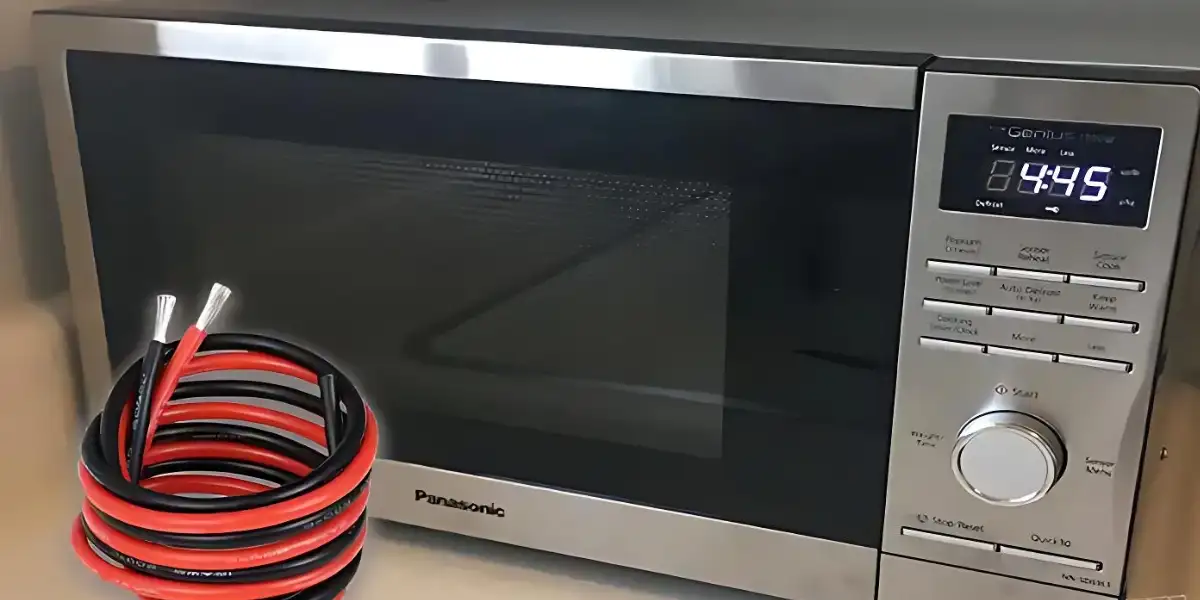

Generally speaking, NM-B Romex is often used for wiring electric stoves, ovens, and ranges.

Common wire sizes for these appliances include 10/3, 8/3, and 6/3 NM-B cables. These numbers indicate the gauge of the wire and the number of conductors; for example, 10/3 means a 10-gauge wire with three conductors.

These cables are safe, have the right design for wiring kitchen appliances, and are relatively easy to install.

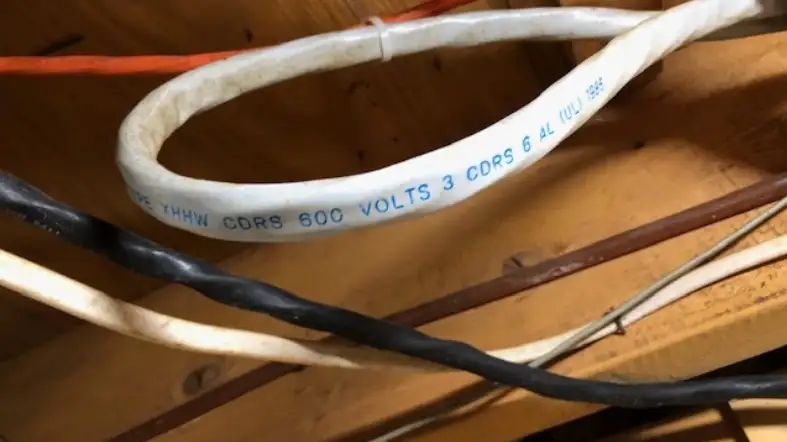

For a 240-volt electric stove, a common setup requires a 50-amp double-pole circuit breaker with a #8 gauge copper wire or a #6 gauge aluminum wire.

Another common setup for plug-in ranges with the oven below recommends a 40-amp breaker with a wire size of #8 AWG copper or #6 AWG aluminum.

However, it’s essential to consult your oven’s user manual or the manufacturer for the specific electrical requirements of your appliance.

This is because the correct wire and breaker size may vary depending on the particular make and model of your oven.

Before embarking on any electrical installation work, it’s crucial to adhere to local building codes and regulations.

It is highly recommended that you consult a certified electrician for this type of work to ensure that the installation is both safe and up to code.

If your breaker panel is far from the oven’s location, the wire gauge may need to be increased to reduce voltage drop over the distance.

Always ensure that the wiring is carried out in accordance with the (NEC) or other local codes to ensure safety.

Types of Wires Suitable for Ovens

There are several types of wires that are suitable for ovens.

Let’s take a closer look at each type and their advantages and disadvantages.

Copper Wires

Copper wires are the most common type of wire used for ovens.

They are known for their high conductivity and durability.

Advantages

- High conductivity.

- Durable.

- Resistant to corrosion.

Disadvantages

- More expensive than other wire types.

- Can be difficult to work with due to its stiffness.

Aluminum Wires

Aluminum wires are another option for oven wiring.

They are less expensive than copper wires but have lower conductivity.

Advantages

- Less expensive than copper wires.

- Lightweight and easy to work with.

Disadvantages

- Lower conductivity than copper wires

- More prone to corrosion

Stranded Wires

Stranded wires are made up of several smaller wires twisted together.

They are more flexible than solid wires and are easier to work with.

Advantages

- More flexible than solid wires.

- Easier to work with.

Disadvantages

- Can be more difficult to terminate than solid wires.

Solid Wires

Solid wires are made up of a single, solid conductor.

They are less flexible than stranded wires but are easier to terminate.

Advantages

- Easier to terminate than stranded wires.

Disadvantages

- Less flexible than stranded wires.

How to Determine the Right Wire Size for Your Oven

To determine the right wire size for your oven, you need to consider several factors.

Here’s a step-by-step guide:

Understanding Oven Wattage

The first step is to determine the wattage of your oven.

This information can usually be found on the oven’s label or in the owner’s manual.

Calculating Amps

Once you know the wattage of your oven, you can calculate the amps by dividing the wattage by the voltage.

For example, if your oven has a wattage of 4,000 watts and operates at 240 volts, it will draw 16.67 amps (4,000 / 240 = 16.67).

Checking Electrical Codes

It’s important to check your local electrical codes to ensure that your wiring meets the required standards.

In most cases, the National Electrical Code (NEC) will provide guidance on wire sizing.

Importance of Wire Gauge

The wire gauge refers to the thickness of the wire. The thicker the wire, the more current it can safely carry.

It’s important to choose a wire gauge that is appropriate for the amps drawn by your oven.

Factors Influencing Wire Size Selection for Ovens

There are several factors that can influence the wire size selection for ovens.

These include:

Oven Wattage and Voltage

The wattage and voltage of your oven will determine how much current it draws.

This will influence the wire size needed.

Length of Wire Run

The length of the wire run can also influence the wire size needed.

The longer the wire runs, the larger the wire size needed to account for voltage drop.

Ambient Temperature

The ambient temperature can also influence wire size selection.

Higher temperatures can cause wires to heat up, which can reduce their current-carrying capacity.

Electrical Codes and Regulations

Local electrical codes and regulations will provide guidance on wire size selection.

Safety Considerations

Safety should always be a top priority when selecting a wire size for an oven.

Cost and Availability

The cost and availability of different wire sizes may also influence your selection.

Type of Oven (Conventional, Convection, etc.)

The type of oven you have may also influence your wire size selection.

Future Upgrades

If you plan on upgrading your oven in the future, it may be wise to choose a larger wire size now to accommodate future upgrades.

Insulation Type

The type of insulation used on the wire can also influence wire size selection.

Benefits of Choosing the Right Wire Size for Oven

Choosing the right wire size for your oven has several benefits.

These include:

Safety

Choosing the right wire size for your oven is crucial for ensuring safety.

The wire size must be able to handle the electrical load of the oven without overheating or causing a fire hazard.

Efficiency

By having an accurate ratio of the size of the range to the size of the wall oven wire, the efficiency difference can be significant.

Using the right wire size can help ensure that your oven operates at its maximum efficiency, saving you money on energy costs.

Prevent Circuit Overload

The ampacity of the stove is calculated when it is at total capacity or very close to it.

This is done in order not to strain an electrical circuit.

Using the right wire size can help prevent circuit overload and potential damage to your electrical system.

Compliance with Electrical Codes

The National Electrical Code (NEC) has specific requirements for wire sizes and types used for electric stoves, ovens, and ranges.

Choosing the right wire size ensures that your oven installation is in compliance with these codes.

Ease of Installation

Using the correct wire size and type can make the installation process easier and more straightforward.

For example, NM-B Romex is a popular type of wire for electric stoves, ovens, and ranges because it has the right design for wiring kitchen appliances, is safe, and is easily installed.

Risks of Using Incorrect Wire Size for Ovens

Using an incorrect wire size for your oven can have several risks.

These include:

Overheating

If the wire size is too small for the oven’s current draw, the wire can overheat.

This can cause the insulation around the wire to melt, which can lead to a short circuit or even a fire.

Reduced Performance

If the wire size is too small, it can cause a voltage drop.

This means that the oven may not receive enough power to operate at its full capacity, which can result in reduced performance and longer cooking times.

Damage to the Oven

Using an incorrect wire size can also cause damage to the oven itself.

If the oven is not receiving enough power, it may cause the heating elements to fail prematurely or other components to malfunction.

Safety Hazards

Using an incorrect wire size can create safety hazards.

For example, if the wire overheats and causes a fire, it can put you and your family at risk.

FAQs About Oven Wire Sizing

What is the standard wire size for ovens?

There is no standard wire size for ovens as it depends on several factors, including the oven’s wattage, voltage, and the length of the wire run.

Can I use aluminum wires for my oven?

Yes, aluminum wires can be used for oven wiring.

However, they have lower conductivity than copper wires and are more prone to corrosion.

Do I need a separate circuit for my oven?

Yes, most ovens require a dedicated circuit.

This means that the oven should be connected to its own circuit breaker in your electrical panel.

Is it safe to DIY oven wiring?

It is not recommended to DIY oven wiring unless you have experience and knowledge in electrical work.

It’s always best to hire a licensed electrician to ensure that your wiring is done safely and correctly.

How often should oven wiring be inspected?

It’s a good idea to have your oven wiring inspected every few years to ensure that it is still in good condition and meets current safety standards.

Conclusion

Choosing the right wire size for your oven is crucial for safety and efficiency.

By considering factors such as oven wattage, voltage, length of wire run, and local electrical codes, you can select the appropriate wire size for your needs.

Remember to always prioritize safety when working with electricity and hire a licensed electrician if you are unsure about any aspect of oven wiring.