Are you looking for an air compressor to power your air tools, but not sure what size you need?

In this blog post, we’ll reveal what size air compressor do I need for air tool and discuss the factors that affect the size of the air compressor. We will also cover the type of tools you’ll be using to the number of tools you’ll be running at once.

What Size Air Compressor Do I Need For Air Tools?

For most common air tools like impact wrenches, ratchets, and airbrushes, a 2-3 horsepower air compressor with a tank size of 20-30 gallons is sufficient. Air compressors in this range can provide the required CFM and PSI for operating standard pneumatic tools. Larger tools may need 5 HP compressors.

How To Determine Your Air Compressor Size?

Determining the appropriate size for your air compressor is essential to ensure optimal performance and efficiency.

Here are the steps to follow to determine the right size for your needs:

Determine the Required CFM

The first step is to determine the required cubic feet per minute (CFM) for your air tools or equipment.

Most tools have a CFM rating listed in their user manual or on the tool itself. If not, you can find CFM charts online that provide average CFM ratings for various tools.

Consider the Duty Cycle

The duty cycle refers to the amount of time the compressor will run in a given time frame.

If you will be using your air compressor for extended periods, you will need a larger unit with a higher duty cycle.

Account for Pressure Drop

Pressure drop occurs when air moves through hoses and fittings, causing a decrease in pressure.

To account for this, add 10% to the CFM requirement.

>> What size allen key for delta shower handle?

Calculate the Total CFM Requirement

Once you have determined the CFM requirement, duty cycle, and pressure drop, you can calculate the total CFM requirement.

Multiply the highest CFM requirement by the duty cycle percentage and add the pressure drop percentage.

Choose an Appropriate Air Compressor Size

Based on the total CFM requirement, you can choose an air compressor size that meets your needs.

It’s generally recommended to choose a compressor with a CFM rating that is at least 1.5 times higher than the total CFM requirement to ensure optimal performance and efficiency.

Consider the tank size, motor horsepower, and other features to ensure the compressor can handle your specific application.

>> What size allen key for garbage disposal?

What Things To Consider Before Deciding On The Air Compressor Size?

Now that you know how much CFM you need from your air compressor, there are a few other factors to consider before purchasing.

In the below section, we will go over a few of these factors. Keep these factors in mind to select the best air compressor for your needs:

Physical Dimensions

What is the maximum amount of storage space on your computer?

When it comes to deciding what kind of air compressor to purchase, one of the first things to consider is how much storage capacity you have.

Compressors with big storage tanks take up more room per square inch. It’s critical to get an air compressor that will fit your needs in your available space.

It’s essential to give your air compressor a three-foot radius around it to allow for adequate ventilation and simple maintenance.

Keep in mind that most air compressors are sold without a storage tank.

If you don’t have room to store an air compressor without a tank, you will have to purchase one separately.

>> What size air compressor for automotive painting?

Air Tool Types & CFM Requirements

The size of an air compressor is essential.

You should first check how much air it delivers (in Cubic Feet Per Minute) and the air pressure rating (PSI) before determining its capacity based on its physical dimensions.

As you know, the average air compressor for home tools is between 10 and 110 CFM. When you check the CFM, you need to remember some crucial points.

The first one is that you need to check the CFM at 90 PSI. Because most air tools run between 90 and 100 PSI.

And the second thing is that you have to look for a higher CFM if you don’t want to take breaks frequently.

>> What air compressor size for a nail gun?

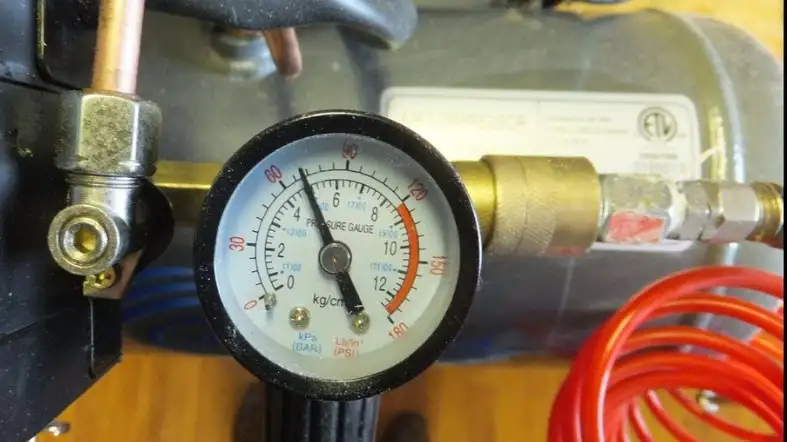

Pressure (PSI)

PSI (Pounds per Square Inch) is a unit of measurement that tells you the air pressure per square inch of an area.

The higher the PSI, the more force the air has. This is why most air tools have a PSI rating- so you can determine if they will be powerful enough for the job at hand.

Keep in mind that you should always get an air compressor with 20% more PSI than what is needed for your tools.

The apparent advantage this creates is that your air tool can function at its best without worrying about pressure dropping below the minimum rating.

However, some air tools require very high PSI ratings. If you plan on using these devices, ensure your compressor can handle them.

>> What air compressor size for impact wrench?

Horsepower (HP)

A horsepower is a unit of measurement that tells you the power output of an engine or motor. The higher the HP, the more influential the engine or motor is.

Most air compressors have an HP rating between 1 and 5. The general rule of thumb is that the higher the CFM, the higher the HP.

However, this isn’t always the case, so make sure to double-check before purchasing an air compressor.

As you can see that choosing a suitable air compressor is not a very easy task. Before making your final decision, you must consider different things like CFM, PSI, HP, and portability.

So, don’t make your decision in a hurry. Take your time, research, and then buy the air compressor that best suits your needs.

>> What air compressor size for framing nailer?

How Much PSI Do I Need For Air Tools?

The average air compressor delivers between 90 and 100 PSI. However, you will need 70 and 90 PSI for most air tools.

The only exception to this rule is if you plan on using very high-pressure air tools, in which case you will need an air compressor to deliver maximum PSI.

This is why it’s vital to get an air compressor with 20% more PSI than what is needed for your tools.

On the other hand, if you only plan on using low-pressure air tools, you can get away with an air compressor that delivers lower PSI.

Here is a table that outlines the recommended PSI (pounds per square inch) range for common air tools:

| Air Tool | Recommended PSI Range |

|---|---|

| Nail gun | 70-120 PSI |

| Staple gun | 70-100 PSI |

| Paint sprayer | 30-50 PSI |

| Air ratchet | 50-90 PSI |

| Impact wrench | 90-100 PSI |

| Air chisel | 90-100 PSI |

| Air hammer | 90-100 PSI |

| Die grinder | 90-100 PSI |

| Sandblaster | 90-150 PSI |

FAQs about what size air compressor need for air tools

What Size Air Compressor For An Air Impact Wrench?

An air impact wrench is a powerful tool that can be used for various tasks, such as loosening nuts and bolts, removing tire lug nuts, and more.

For this reason, you will need an air compressor that can deliver at least 90 PSI.

What Size Air Compressor For An Air Ratchet?

Air ratchets can work well with an air compressor as long as it can produce 90 to 100 PSI of air pressure.

Air ratchets have little effect on air volume since they can utilize both 1/4 inch and 1/2 inch ratchets at the same time with just 3 CFM of airflow.

What Size Air Compressor For An Air Hammer?

You will need an air compressor that can generate around 90 to 100 PSI of pressure, depending on the size and model of your air tool.

If your air compressor produces 90 PSI, you’ll need around 4 CFM to operate your air hammer at a decent pace.

Final Thoughts

Now you know what size air compressor you need for air tools, it’s time to get out there and buy one.

Just consider all the factors we’ve discussed before making your final decision.

It’s also important to read reviews and compare prices to ensure you get the best deal possible.

We hope this article has been helpful and that you can now buy the air compressor that best suits your needs.